We design and manufacture each gasketed plate heat exchanger (PHE) according to the required specifications : dimensions, pressure, flow rate, fluid type, in and out temperatures, etc…

Our PHE’s can be used in many industries and with all kinds of fluids. In fact, our main customers work in sectors such as food processing (pasteurization and waste heat recovery), pharmaceuticals, HVAC, steel industry and shipbuilding (diesel engine cooling).

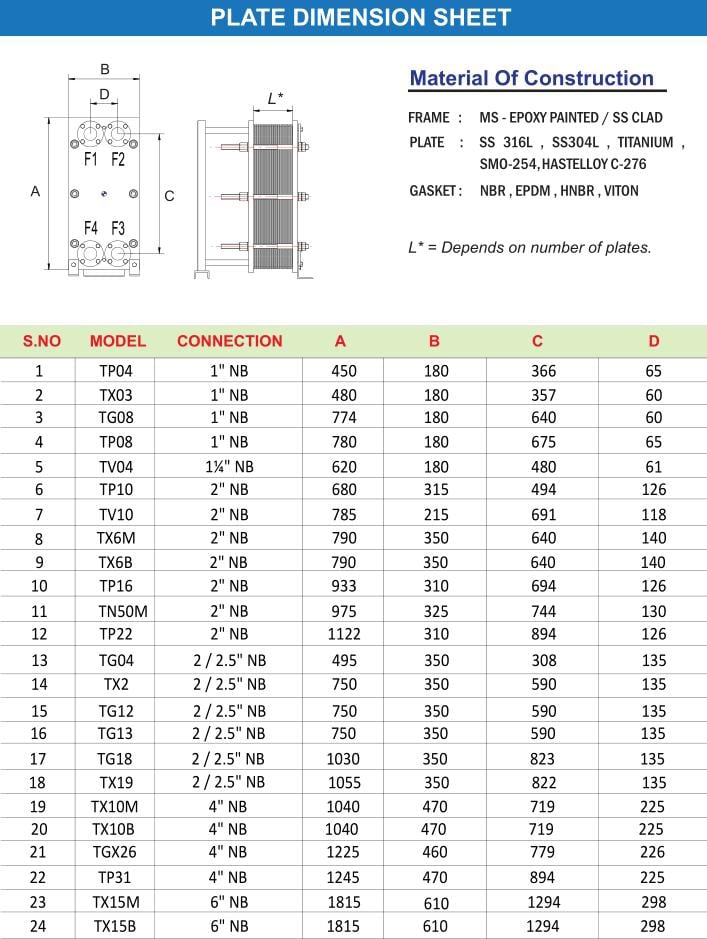

Here are some examples of the materials we use and standard plate heat exchanger dimensions.

Frame: either epoxy painted mild steel or 316 stainless steel

Plates: 316 stainless steel or 304 if needed, titanium, SMO-254, Hastelloy C-276

Gaskets: NBR (nitrile butyl rubberrubber) food grade or non-food grade, EPDM (ethylene propylene diene monomer rubber), HNBR (Hydrogenated nitrile butadiene rubber), Viton

Once we know your exact application we will suggest the most suited materials for the plates and gaskets.

Flow rate: depends on fluid type but up to 180,000 LPH on the 6″ pipe model

Pressure: maximum is 12 bar

Fluids: liquid/liquid or steam (up to 7 bar)

Most of our customers use the following fluids: water, glycol, oil, chemicals, thermic fluids, milk, beer, food

In order to quote a custom PHE we will start by asking you give us the desired specifications:

- primary side fluid + inlet temperature + outlet temperature

- secondary side fluid inlet temperature + outlet temperature

- desired flow rate

- heat load

We also supply replacement plates for many PHE’s made by other manufacturers. Usually with a photo and outside dimensions we can identify the exact spare plate you need.